I purchased this KB&B Yello Bole off Ebay .

I was looking for another 07 billiard as i own a couple and very much like the large bowl, the way they smoke and classic shape of them . This one was listed as a four digit (2807) with the “Honey Cured Briar ” stamping , which made it a pre 1936 Yello Bole .

I thought ,excellent ! I did not have a early four digit 07 as of yet .

Here is one of the Ebay pictures ,

The pipe looked in excellent condition for its age but i did notice a couple of odd things about it . The band was wider than normal and after looking up the 28 two digit code it should have been stained dark . From the other pics of the pipe that was on the listing the grain was very bland and had a large defect in the front of the bowl . I thought thats odd the pipe should have most likely been rusticated and stained dark . ( All this has bearing on the pipe trust me ) I thought maybe it had been stripped or something to that effect .

Well i went ahead and bid anyway as the starting bid was quite low and the pipe looked really nice in the pictures .

A few days later when it arrived and got it in hand i noticed that it had more weight to it than a regular 07 Yello Bole .The pipe though was very nice shape and had not been refinished . It was a lightly smoked four digit pre 1936 07 that somehow escaped the factory with just a natural finish on it .The bowl and stem looked more hefty and beefy than a normal Yello Bole also . I was very happy with it .

Well i grabbed the stem to turn it loose from the shank and my heart sank . The stem pulled right off the tenon !

The odd thing was it was had never been glued . I could tell by the tenon that someone had tried to free it from the shank before from the tool marks on it . Well i wrapped a rag around it and try to free it myself . Would not budge . I could also not blow or get a draw from it .I thought someone had wedged something in it and it was stuck in the stinger.

I placed the pipe in the freezer for a few hours and when i got it out i agian wrapped a rag around the exposed tenon and gave it a twist . The tenon came out alright but i also found a surprise !

Out came a very odd looking contraption of a “stinger ” i had about ever seen .I was thinking to myself …..”.Aww man what kind of junk is this “. “Wonder if i can re -stem it without that thing in it ?”

Then i got curious and started checking it all out more closely . I got out my small flashlight and looked down the stem . It was full of corrosion and had a inner metal sleeve that ran down the shank to the bowl.

Well i grabbed a piece of Scotch Brite pad and rolled it up around a small screwdriver and cleaned it out then applied mineral oil .

Well i stuck it all back together and low and behold it got a good draw now and i noticed a odd thing , i could not blow back up into the pipe . The gizmo was not a stinger but a valve .

Now im really curious about the pipe . I put it aside and for several days when i had free time i researched on the web to see if i could find ANYTHING about it ………………nothing , nada ,zilch!

With no patent number on it i couldn’t even look that up .After some thinking i came to a theory that i will share at the end of the article .

Well i debated whether to even touch this pipe or do anything to it at all. I decided to just do as little clean up and work on it as possible . Just enough to preserve what i had. I cleaned the valve gizmo and sanded a small amount of chatter off the stem and gave the pipe a light wax and buff .There is some dings still in the bowl and stem but i did not want to take anymore material off the pipe . You can always take off material and original finish from a pipe but you can never put it back on .

Here is the finished pipe .

The stamping’s are like new

It has a larger stem slit than a normal Yello Bole

Now im gonna go in more detail about the “Valve” as i think its a very interesting and unique system .

The pipe has to break down into three pieces in order to maintain and clean this system.

If you insert the valve into the stem and then install it into the shank it fits pretty loose ….this does not work well.

You should push the valve in the the shank with a good push so it will seat itself into the shank and bowl . Then pop on the stem . It has a good secure fit like this .

The valve is solid in the middle so you can not run a pipe cleaner through it while it is installed in the pipe .

It does have airways on both ends

Three is two openings on the bowl end . Im using a pipe cleaner to show the airflow.

On the tenon end other than the airway on the shaft there is two holes that are on opposite sides and i believe these are more for cleaning that airflow

I also found this while cleaning up the Valve . It has a bearing in it like a pea in a whistle . I pushed it to the top in this picture with a pipe cleaner . This is what causes air to blocked from being blown back up into the bowl . It makes it a one way valve .

Now here is my theory on the “valve” pipe .

I think its a prototype and possibly the only one built.I think the pipe was pulled from production before staining and finish and was fitted with the parts you see now . It was tested briefly and either failed to make production from the complicated way you have to maintain and clean this pipe or just the sheer cost of producing such a pipe .More than likely both reasons. Since the design did not pass muster a patent number was never applied for and the ‘Valve” was gone with no way to research it patent wise .

I think someone like the engineer or designer who came up with this pipe saved it as a momento or keep sake . It was put up and forgot about until the person i purchased it from picked it up at a Palm Spring estate sale .

That is MY theory anyway .

I have smoked a few bowls out of the pipe since preserving it .

It smokes very well .It is the driest smoking pipe i have ever used.The “valve” traps about every bit of the moisture from the tobacco .It does not gurgle AT ALL , which surprised me after all the moisture it traps.

Once you take the system apart during or after a smoke there is A LOT of moisture trapped in and on the “valve”.

You HAVE to clean this pipe after every smoke and let it dry thoroughly in the shank or it will most likely corrode very fast , even with only a couple of smokes .

Does the positives out weight the negatives? I don’t think so .

Its a over complicated and over engineered pipe that would be hard to use other than sitting at home with a place and resources too take it apart and clean it EVERY time you smoke it.

Take it to a ball game ? A fishing trip? Carry it on a long walk ? Forget it .These are the quality’s that make a Yello Bole great in my eyes. A good smoking , inexpensive ,simple pipe that you can take anywhere .

Another quirk about this pipe is sometimes you pull the stem back off the tenon while its still in the shank . Then it requires you to use a type of tool to twist and remove the valve and tenon out . ( I use a pair of small needle nose pliers and a rag or paper towel )

Its is though a unique and possibly a one of a kind piece of KB&B history .

Well i hope you enjoyed looking at this old ,unique and odd Yello Bole . This is one pipe that really caught me by surprise .

*UPDATE*

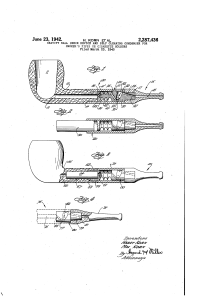

After posting this Sean and fellow member of the Dr. Grabow Collectors Forum found the patent

http://www.google.com/patents/US2287436

Since the pipe predates the filing by at least four years , maybe the pipe was made by Yello Bole as a commission ? Maybe it was tried by them and rejected but the inventor kept the pipe as a working prototype for applying for the patent ?

It seems my theory of this being a prototype may be correct .

Even if there was a attempt to produce the pipe , the filling and publishing of the patent is right around the beginning of World War II . The much needed metal to make this pipe would have been the straw to break the camels back of this pipe design seeing the light of day at the this moment in time .

August 19, 2015 at 7:01 pm

Very unique find. Congrats!

LikeLiked by 1 person

August 19, 2015 at 7:59 pm

Thanks Joe .

I hope someday i may be able to find out more about it ,but not likely im afraid.

LikeLike

August 19, 2015 at 11:15 pm

A “back flow preventer” ! Certainly an interesting piece! Never saw anything like it!

LikeLiked by 1 person

August 20, 2015 at 1:57 am

Its definitely a “odd duck” pipe .

The idea has merit, its just not that needed unless you slobber like a St. Bernard when you smoke a pipe .

LikeLike

August 20, 2015 at 2:48 am

That certainly is a unique system. Nice work on the preservation. You should email pipephil.eu about this pipe. It seems like this is something they’d be interested in adding to database.

LikeLiked by 1 person

August 20, 2015 at 2:56 am

Thanks Dave .

Im not sure how they would list the pipe as it was never given a model name like “Imperial” or “Premiere “. I may send them a link though and see if they would be interested.

LikeLike

August 20, 2015 at 6:03 am

Wow! What you have there, Troy, is a pipe collector’s dream. I think you’re absolutely right about it being a prototype and probably one of a kind. Congratulations on an awesome find!

LikeLiked by 1 person

August 20, 2015 at 9:37 am

Thank you Anthony

LikeLike

August 20, 2015 at 3:46 pm

I’ve certainly never seen anything like it. Very cool find my friend.

LikeLiked by 1 person

August 21, 2015 at 5:41 pm

Amazing. Never saw a “thing” like this. Unfortunatly I cannot give more information about this oddity

LikeLiked by 1 person

August 21, 2015 at 8:35 pm

Thanks for looking Phil !

If you haven’t seen anything like it ,then i know it is not likely anymore of these pipes are out there .

LikeLike

August 23, 2015 at 2:19 pm

Reblogged this on rebornpipes and commented:

Another blog post of Troy’s on a unique Yello Bole pipe. Well done Troy.

LikeLiked by 1 person

August 23, 2015 at 8:01 pm

Very cool pipe Troy. Thanks for sending me the link and the “recipe” earlier. Interestingly, I actively seek out “system” pipes myself. I have quite a few pipes with strange filter/traps/”improvement” devices etc.

John

LikeLiked by 1 person

August 24, 2015 at 3:49 am

Very interesting moisture management system. You have a one in a million find there. Makes collecting all the more fun.

LikeLiked by 1 person

August 24, 2015 at 8:44 am

Thanks Al

I have to say ,although complicated and quirky the system does work very well .

LikeLike

Pingback: A Unique 1940’s KB&B Yello-Bole Propeller Apple | Baccy Pipes